The R/V Marcus G. Langseth Team

From Bridge to Engine

The crew of the R/V Marcus G. Langseth (some of whom are pictured above) are experienced and dedicated sea-going professionals bound by the goal of facilitating scientific knowledge and ocean exploration. Whether it’s investigating seismic activity, mapping the ocean floor, or enabling deployment of CTD (Conductivity, Temperature, and Depth) operations, the crew, led by Captain Breckenridge C. Crum (pictured above, top far left), has been instrumental to the operations of the 2024 reoccupation of the A13.5 transect. Nearly every one of our blog posts have included shoutouts for different members of the crew, from those keeping us nourished during our daily 12-hour shifts for the past seven weeks, to those assisting us with our technology needs, along with others charged with maintaining the ship and those involved with facilitating CTD rosette and float deployments.

Captain Breckenridge Crum, Aaron Martin, Lamont-Doherty Earth Observatory (LDEO) Marine Science Technician, and Todd Jensvold, Lead LDEO Marine Science Officer, load testing the spare winch (from left to right).

From left to right: Todd Jensvold (LDEO), Eric Wisegarver (NOAA PMEL), Evan Josza, (UW CICOES/NOAA PMEL), and Christian Saiz (UM CIMAS) recovering the CTD.

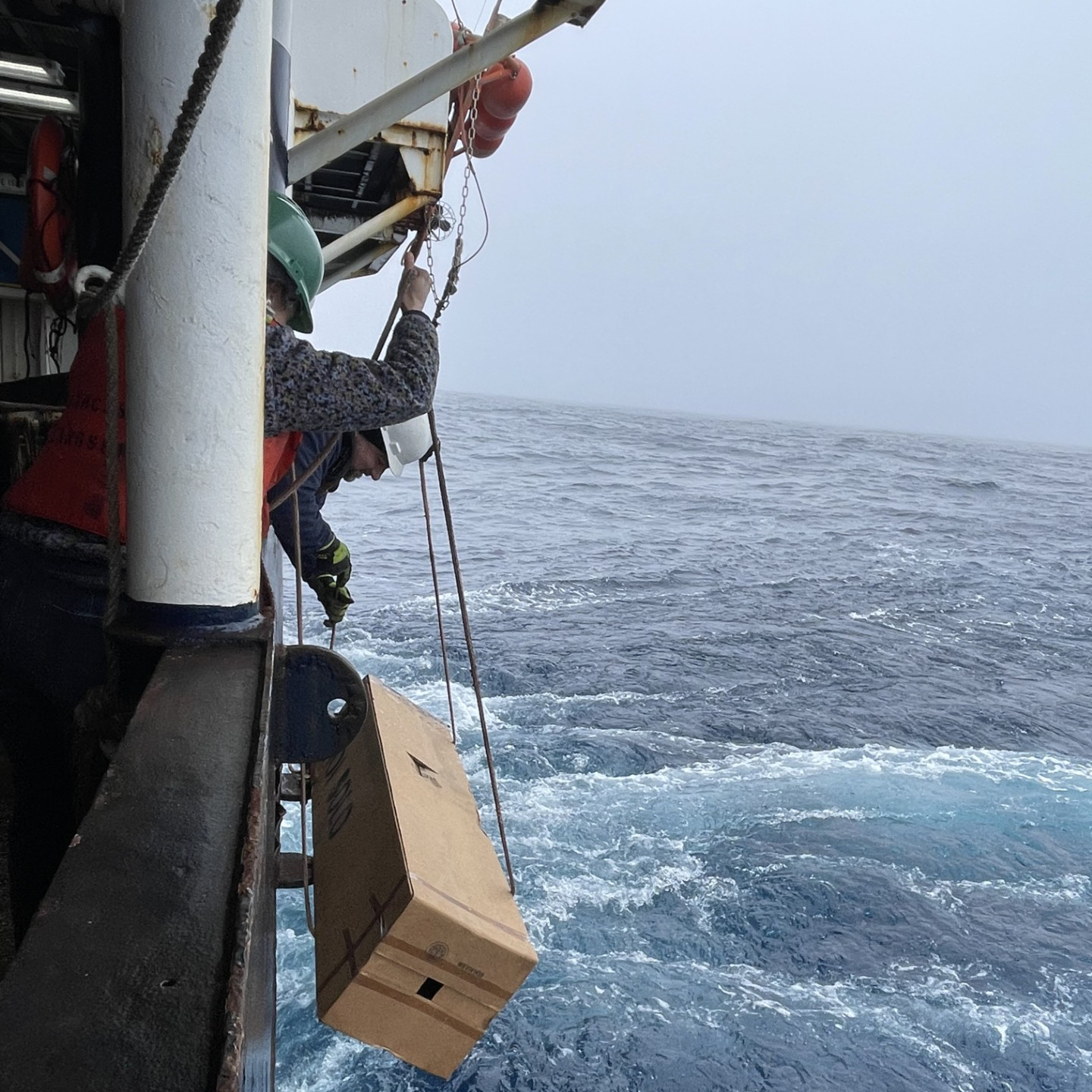

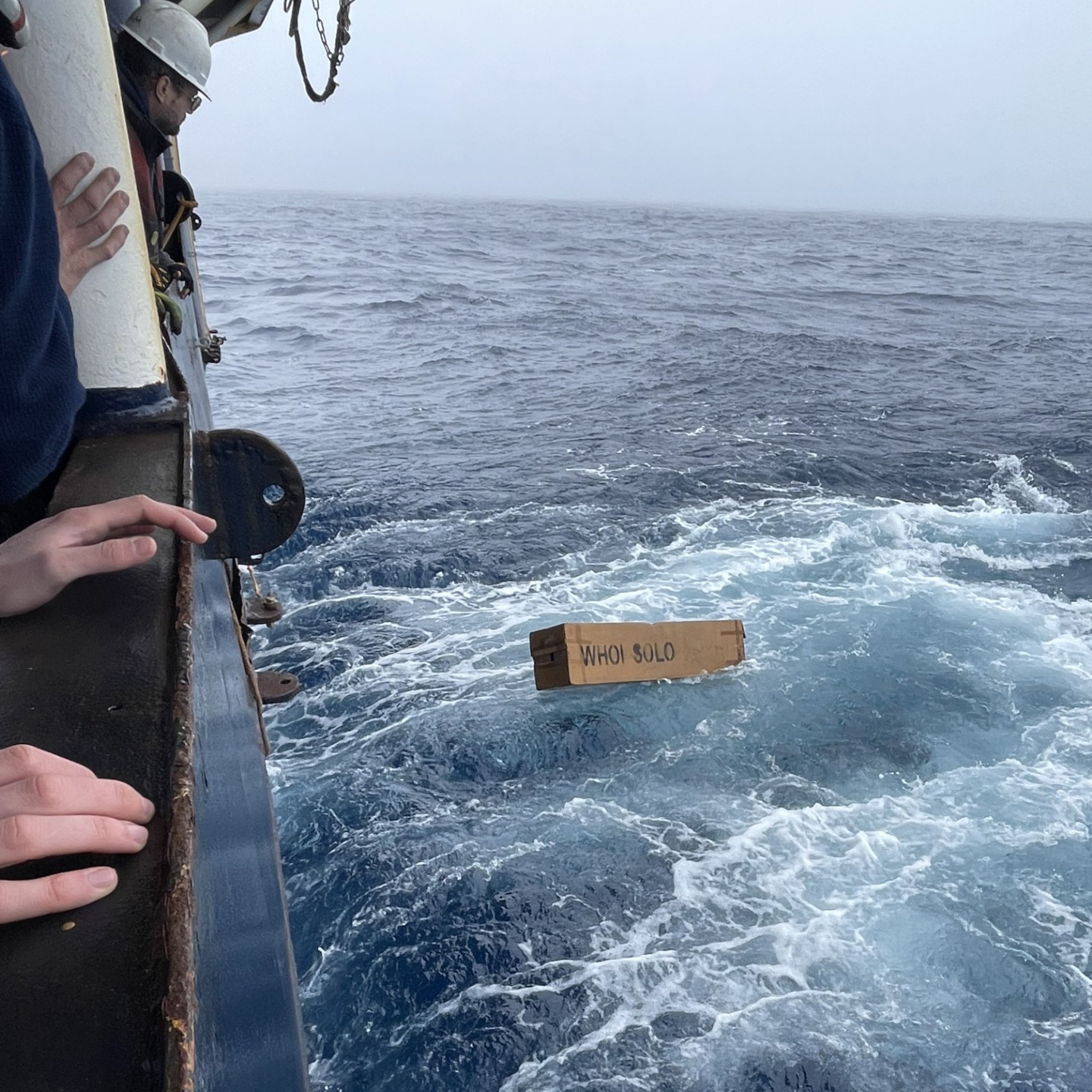

Today, crew members once again assisted Chief Scientist Zachary Erickson (NOAA PMEL) and Co-Chief Science Jesse Anderson (ESR) with the deployment of a Core Argo float. These floats are deployed inside a biodegradable cardboard box held together with water soluble tape, a packing method that is an environmentally friendly way to protect the delicate instrument from damage during deployment.

Koray Ergun, Lamont-Doherty Earth Observatory (LDEO) Marine Science Technician, Aaron Martin, and Todd Jensvold bring the Core Argo float to the stern of the Langseth.

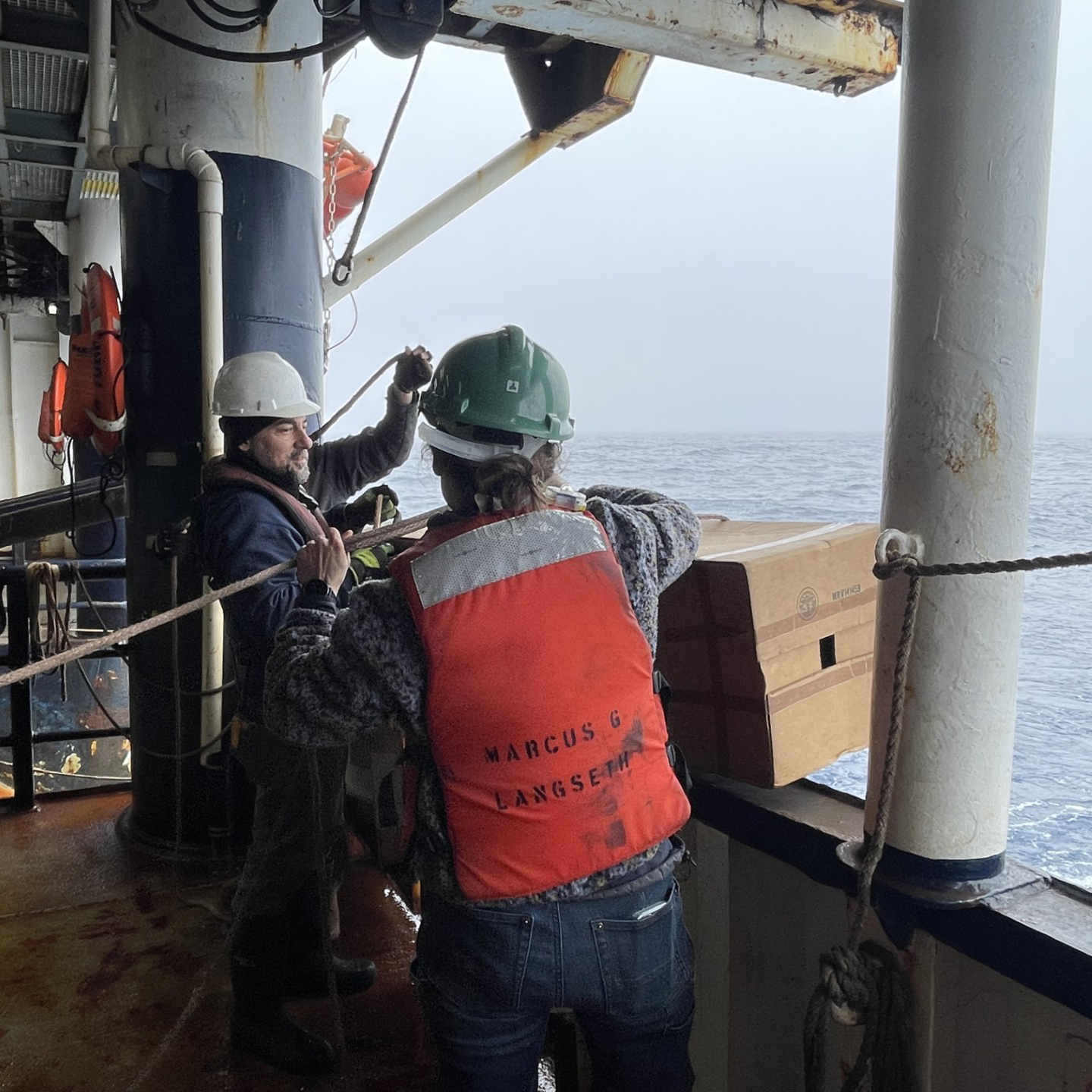

Todd Jensvold, Koray Ergun, and Aaron Martin assist Chief Scientist Zachary Erickson (NOAA PMEL) and Co-Chief Scientist Jesse Anderson (ESR) to prepare the Core Argo float for deployment off the stern of the Langseth.

Koray Ergun and Jesse Anderson position the Core Argo Float, in its biodegradable cardboard box, near the edge of the ship in preparation for deployment.

The Core Argo float is gently lowered into the water ensuring that it does not touch the side of the ship or impact the surface of the water in a rough manner.

Not long after deployment, it drifted away from the ship, the release box slipped loose, and the float was on its way!

During this activity, many others were actively assisting with float deployment from behind the scenes. These hidden heroes specialize in navigation, communication, safety, engineering, mechanical operations, and other diverse skills that maintain the essential operations of the ship. Without these crew members, spanning from the bridge to the engine room, our science objectives could not be realized.

The bridge crew plots strategic courses monitoring safety precautions, weather patterns, interactions with other vessels, and compliance with international regulations. Recently on this cruise, our bridge crew ensured that we safely managed through the fog and around icebergs (look for more on this in an upcoming blog!). They keep the ship on course and ready to respond to any situation that may arise.

Joselyn White, 2nd Mate, monitoring the Bridge, with Gerry McLamon and Lindsay Daniels, both Able Seamen (AB), standing watch on R/V Marcus G. Langseth.

Thomas Wakley, 3rd Mate, monitoring the Bridge.

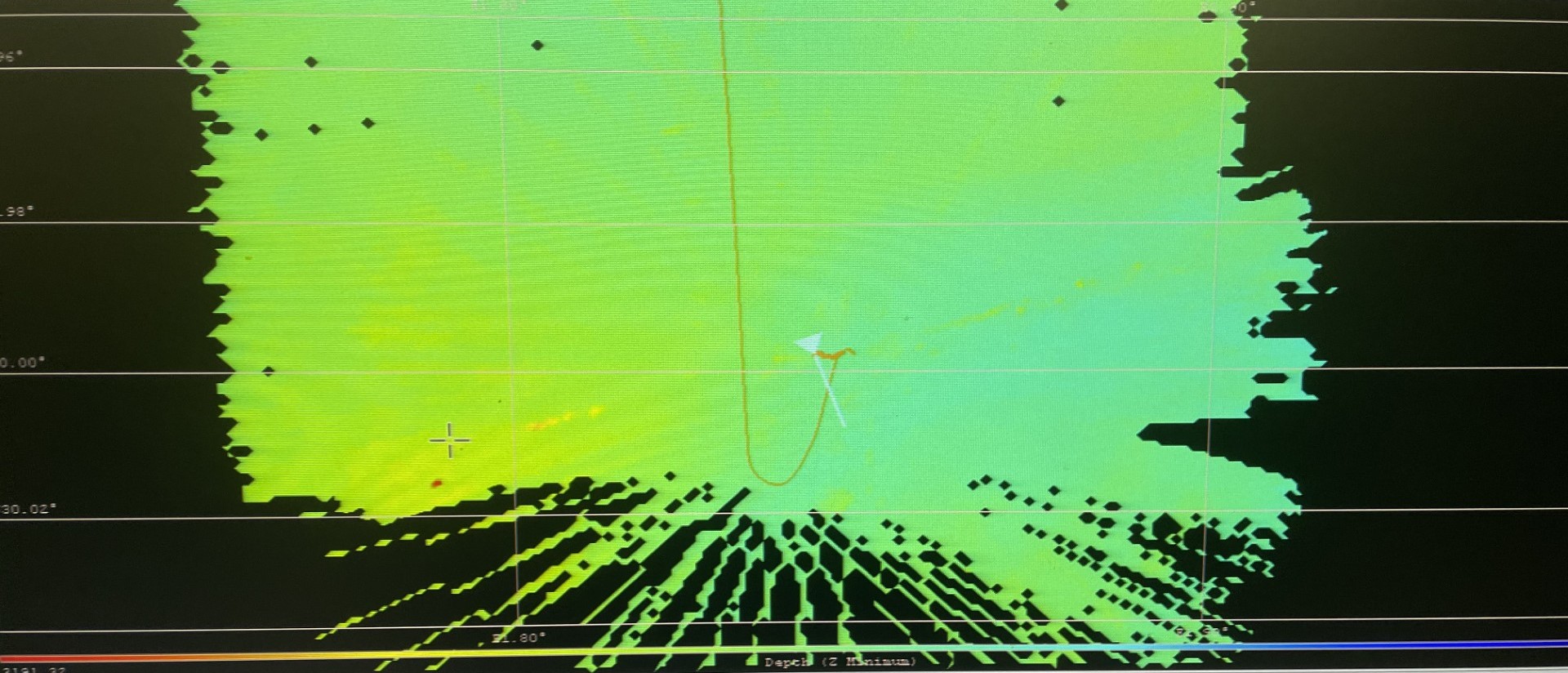

During many of the CTD deployments we recently completed along A13.5, which can take up to four hours, the crew on the bridge, working in tandem with the engine room, keeps the ship oriented in the most advantageous position for the cast. This can take different forms depending on the conditions and the ocean floor beneath us. The easiest option is to drift with the currents during the cast, but this can lead to problems if we drift over the cable, causing it to run up against the hull, or if there is rapidly changing ocean bathymetry beneath us – in which case we might drift into significantly shallow waters and risk hitting the ocean floor with our CTD. In these cases, we often request the ship to hold position, which is not always an easy task in some of the storms we have weathered! The visualizations below show the maneuvering it took to stay on one of our CTD stations for a long cast during a storm, circling a different site to determine potential depth hazards that need to be avoided during the predictable drifting that would likely occur as the strong winds and waves rocked the ship, and one of the many areas of unique sea floor topography that required careful monitoring of bathymetric data for safe CTD deployment.

Track of the Langseth working to hold a steady location while on Station 41 (Latitude: 16° South, Longitude: 1° East), during an extremely windy, four hour CTD cast with large ocean surface waves on February 22nd.

The Langseth conducting a bathymetric survey to determine potential drifting hazards prior to Station 62 (Latitude 26° South, Longitude 1° East) on February 28th.

The Langseth maneuvering between Stations 74–76 (Latitudes 32–33° South, Longitude 1° East) on March 3rd.

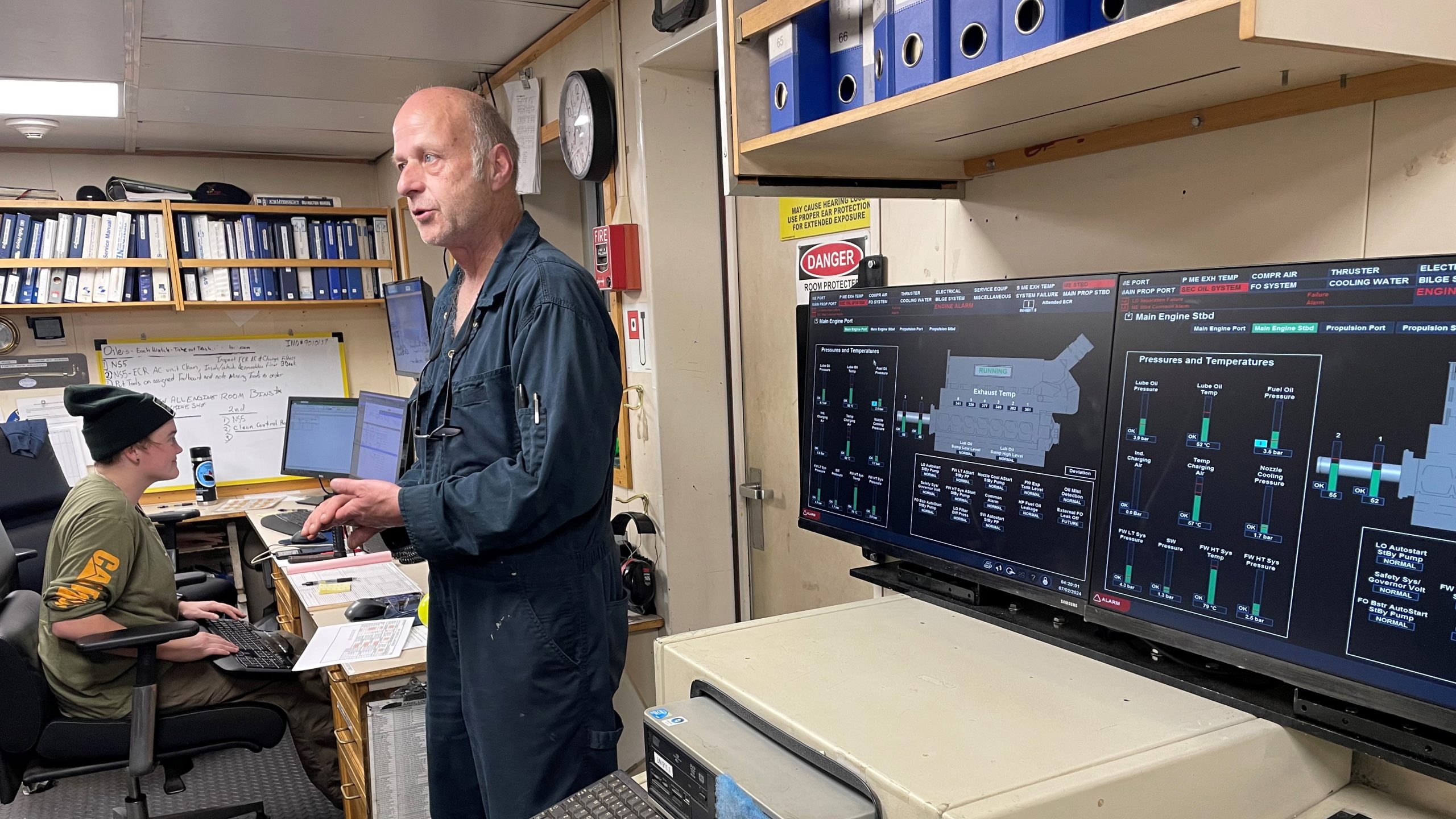

This type of maneuvering requires constant communication between the bridge and the engine room, which was one of the first areas we toured when we boarded the Langseth. Sam Romey, Langseth Chief Engineer, and Mike Hill, a seasoned sea-going mechanic and electrician, explained that engineers in the engine room continuously monitor the performance of the ship’s propulsion and power generation systems, as well as other machinery such as pumps, compressors, and the ship’s cooling system, to ensure safe and successful operations. The engine room team performs regular maintenance and repairs to uphold the ship’s systems’ dependability and efficiency. In addition to propulsion, the engine room also generates the electrical power needed for onboard systems such as navigation equipment, communication systems, lighting, and climate control used by everyone on the ship.

Sam Romey, Chief Engineer of the Langseth, with Chief Scientist Zachary Erickson (NOAA PMEL) and Co-Chief Scientist Jesse Anderson (ESR) on the top deck of the Langseth.

Mike Hill, Langseth electrician, explains the intricacies of the powerful engine system of the Langseth and the critical work of the bridge and engine room crew. Sara Wright, Second Engineer (2A/E), at the computer screen, documenting fuel consumption rates.

![PIC 16 Engine Room Equipment R/V Marcus G. Langseth engine room and Ariel compressors for the port side (on the left) and starboard side (on the right) of the ship. These air compressors are the largest in the world found on a research ship.]](https://www.go-bgc.org/wp-content/uploads/2024/03/PIC-16-engine-room-equipment-scaled.jpeg)

R/V Marcus G. Langseth engine room and Ariel compressors for the port side (on the left) and starboard side (on the right) of the ship. These air compressors are the largest in the world found on a research ship.

Dave Hall, Langseth Oiler, stands watch of the engine.

Some members of the Engine Room Team. Top row, from left to right: Mac Baker, Oiler; Mitchell Paul, Third Engineer (3A/E); and Rudy Florendo, Oiler. Bottom row, from left to right: Sean Sullivan, First Engineer (1A/E); and Sara Wright, Second Engineer (2A/E).

The engine room keeps tabs on machinery status, fuel usage, engine performance, and other crucial operational details, providing ongoing updates to Captain Breckenridge Crum and his crew on the bridge. This constant communication facilitates synchronized decision-making between the bridge and engine room, and the activities carried out by all crew members on board the Langseth, ensuring safe and effective ship operations.

The Science Team of the A13.5 thank the entire crew of R/V Marcus G. Langseth for their support and assistance during the 2024 reoccupation of GO-SHIP’s A13.5 transect. We appreciate each and every one of you!

You can find more information about R/V Marcus G. Langseth at this link.

Some members of the Engine Room Team in front of the Langseth main engine.

Various crew members from all areas of operations on the R/V Marcus G. Langseth.

Teresa Kennedy, CTD Watchstander, 3/19/2024 University of Texas at Tyler; University of Rhode Island.

All pictures by Teresa Kennedy.